RECEIVER TUBES FOR LINEAR CSP (CONCENTRATED SOLAR POWER) APPLICATIONS

RIOGLASS PTR® Receivers

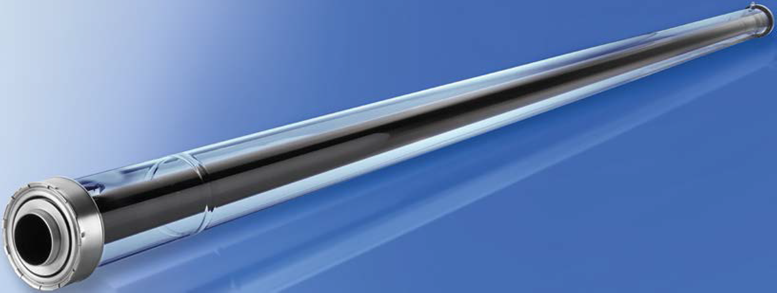

Linear Absorber Tubes or Heat Collecting Elements (HCEs), also simply referred to as Receivers, are used to absorb the concentrated sunlight from the Parabolic Trough [insert link to page with information about PT] collector or the Compact Linear Fresnel [insert link to page with information about CLFR]collector, and transfer the energy absorbed into a Heat Transfer Fluid (HFT) that is pumped through the HCEs. This energy in the form of heat, will elsewhere be used or converted into electricity. Rioglass Solar´s product line uses the registered brand name PTR®, which is the abbreviation for Parabolic Trough Receiver. In the picture below you can distinguish the main elements that form the HCE. Rioglass Solar offer its PTR® product line in different product variations:

• Diameter steel tube: PTR® 70, PTR® 80, and PTR® 90 mm

• Length steel tube: 4.060 mm (PTR® 70 and PTR® 90) and 4.386 mm (PTR® 80)

• Different max. T: 4G for standard HTF or other generations for high temperature Applications

Rioglass Solar S PTR® receiver benefits at a glance:

• Extremely high solar absorption

• Reduced heat losses

• Larger active area

• Increased thermal heat production

• Long-term hydrogen prevention

Technology based on the largest installed base in the CSP industry of HCE tubes

Please contact us for more information.

The Rioglass Solar PTR® receivers, which is an advanced technologically tubular heat collecting element (“HCE”) for Concentrated Solar Power plants (CSP) based on Parabolic Trough technology and uses synthetic thermal oil as heat transfer fluid (HTF).

The Rioglass Solar PTR® is the 4th generation of receivers that has been developed based on more than 15 years of proven track record of developing HCEs for the solar thermal industry by Schott Solar and Rioglass Solar

The PTR® receivers are built and tested for extreme environmental conditions and complies with strict standards and quality for Power Piping as well as for Boiler & Pressure vessel (e.g.: ASME B31.1, ASME VIII)

PTR® receiver product overview (standard versions):

| PTR® 70-4G | PTR® 80-4G | PTR® 90-4G | |

|---|---|---|---|

| Average solar absorptance (ASTM) | α ≥ 0,960 (95,5%) | α ≥ 0,955 (95,5%) | α ≥ 0,960 (95,5%) |

| Average thermal emittance (400°C) | ε ≤ 0.095 (9,5%) | ε ≤ 0.095 (9,5%) | ε ≤ 0.095 (9,5%) |

| Steel tube outer diameter | 70 mm | 80 mm | 88.9 mm |

| Wall thcikness | 2,0 mm | 2,0 mm | 2,5 mm |

| Length (at 20°C ambient temperature) | 4.060 mm | 4.386 mm | 4.060 mm |

| Effective aperture length (at 350°C working temperature) | ≥ 96.7 % of the bulk length | ≥ 96.7 % of the bulk length | ≥ 96.7 % of the bulk length |

| Weight (approx.) | 25 kg | 31 kg | 35 kg |

| Vacuum | residual gas pressure ≤ 10-4 mbar | residual gas pressure ≤ 10-4 mbar | residual gas pressure ≤ 10-4 mbar |

| Glass Enveloppe | Borosilicate glass | Borosilicate glass | Borosilicate glass |

| Outer diameter | 125 mm | 136 mm | 142 mm |

| Antireflective coating | ≥ 95,0% of aperture length | ≥ 95,0% of aperture length | ≥ 95,0% of aperture length |

| Average solar transmittance | τ ≥ 0.970 (97 %) | τ ≥ 0.9652 (96,5 %) | τ ≥ 0.970 (97 %) |

| HTF | Non-corrosive thermal oil with an effective partial pressure of dissolved hydrogen of pH2 < 30 Pa | ||

| Operating pressure | ≤ 37 barg | ||

| Concentration ratio | C < 100 |

For different temperature ranges (e.g. silicone oil and molten salt HTFs) Rioglass Solar has specific product variations available. Also specific product aspect can be altered and changed within manufacturable margin. Please contact us in case you have specific requirements.